Economic efficiency and safety with the right tyre pressure

- Tyre pressure monitoring system (TPMS) with auto-location function for Schmitz Cargobull trailers

- Full Service Retread Tyres contract with retreaded tyres in case of replacement

September 2024 – The right tyre pressure plays a vital role when it comes to increasing economic efficiency and safety. The TPMS automatic monitoring function makes it easier to maintain the correct tyre pressure. This significantly improves both driving behaviour and driving safety. The right tyre pressure also plays a decisive role in extending tyre service life, reducing fuel consumption and carbon emissions, and increasing economic efficiency. After all, vehicles stuck with a flat tyre cost time and money.

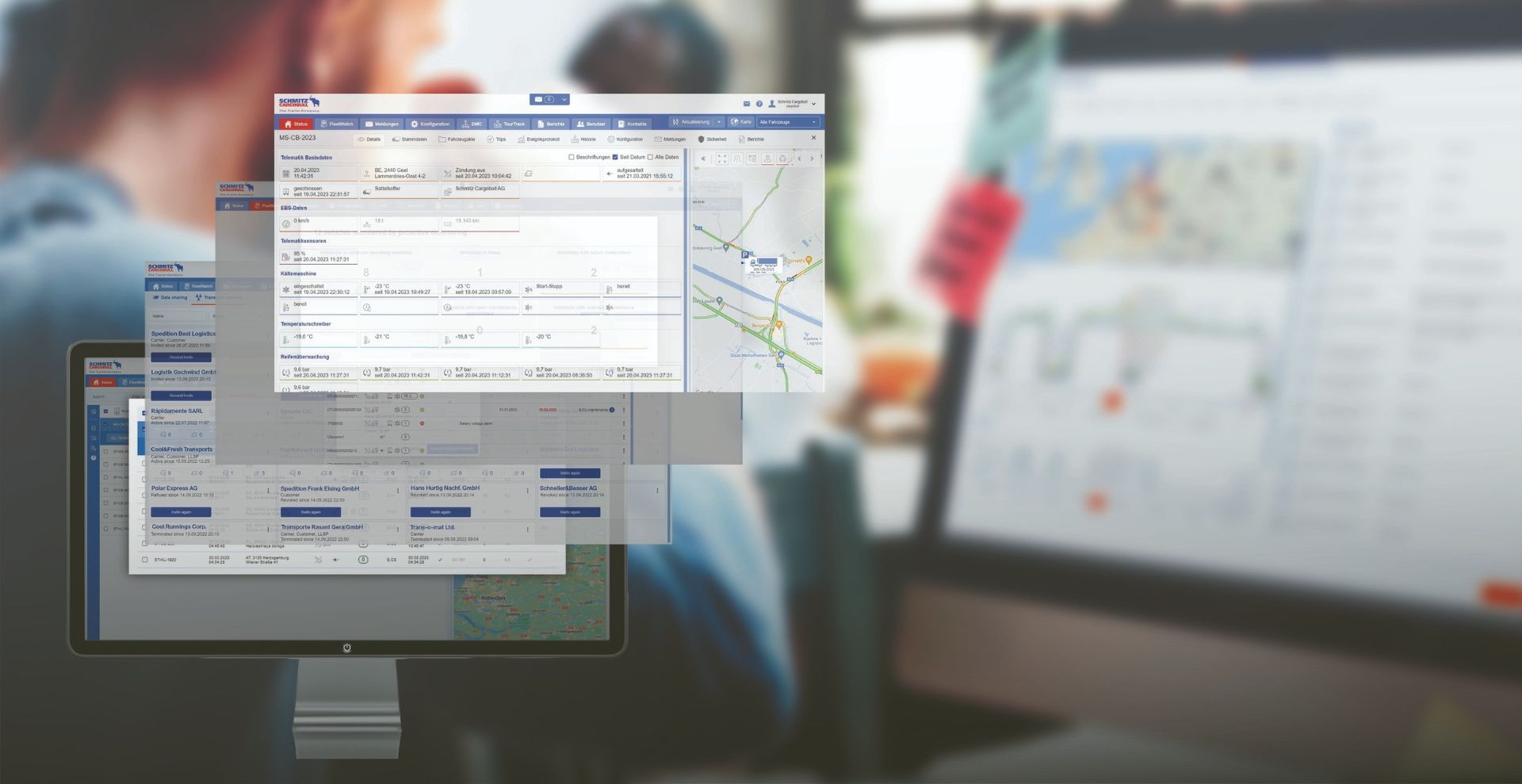

Schmitz Cargobull has been successively installing the TrailerConnect® telematics system in all trailers as a standard feature ex works since 2018. Since the beginning of this year, Schmitz Cargobull has also equipped all of its trailers with tyre pressure monitoring sensors as standard, ensuring that these vehicles already comply with UN ECE R 141 regulation, which will come into force in July 2024. This regulation makes a TPMS mandatory for all newly registered trailers. Schmitz Cargobull’s TPMS monitors the tyre pressure in real time and warns of sudden or gradual loss of pressure or of overpressure.

Auto-location: Automatic assignment of the correct tyre position

With the help of the auto-location function, Schmitz Cargobull TPMS* sensors can be automatically detected and assigned to the corresponding wheel position. The time-consuming and error-prone training and assignment process is no longer necessary. This saves time and money for both customers and workshops. In addition, auto-location offers maximum security and transparency immediately after a spontaneous tyre change or workshop visit. The TrailerConnect® portal can be used to monitor the status of the trailer and tyres easily and conveniently in real time, while e-mail or app notifications can be issued in the event of deviations.

Information display for drivers

Full Service Retread Tyres contract: retreaded tyres in case of replacement

In future, Schmitz Cargobull customers will have the option of choosing retreaded tyres as a replacement, as part of a Full Service Retread Tyres service contract. To date, Schmitz Cargobull vehicles have been fitted almost exclusively with new tyres as replacements. Depending on their quality and condition, tyres in the truck sector can be retreaded up to two times, achieving a useful life of up to 660,000 kilometres. The retreading is carried out in compliance with strict quality regulations and is certified in accordance with ECE regulation 109. The treads are tailored to the specific vehicle types and use, with the aim of continuing to optimise rolling resistance, fuel consumption and mileage even after retreading.

The Full Service Retread Tyres contract won the European Transport Award for Sustainability 2024 from HUSS-Verlag, in the Rental, Leasing, Financing, Service Contracts category.

*The TrailerConnect® TPMS is also technically compatible with the majority of sensors available on the market (EU). Only the original Schmitz Cargobull sensors are compliant with UN ECE R 141 for the TPMS including auto-location function.

About Schmitz Cargobull

Schmitz Cargobull is the leading manufacturer of semi-trailers for temperature-controlled freight, general cargo and bulk goods in Europe, and a pioneer in digital solutions for trailer services and improved connectivity. The company also manufactures transport cooling units for refrigerated box body semi-trailers for temperature-controlled freight transport. With a comprehensive range of services from financing, spare parts supply, service contracts and telematics solutions to used vehicle trading, Schmitz Cargobull supports its customers in optimising their total cost of ownership (TCO) and digital transformation.

Schmitz Cargobull was founded in 1892 in Münsterland, Germany. The family-run company produces around 50,000 vehicles per year with over 6,000 employees, and generated a turnover of around €2.16 billion in the financial year 2024/25. Its international production network is made up of factories in Germany, Lithuania, Spain, Turkey and the UK.

The Schmitz Cargobull press team:

| Anna Stuhlmeier: | +49 2558 81-1340 I anna.stuhlmeier@cargobull.com |

| Andrea Beckonert: | +49 2558 81-1321 I andrea.beckonert@cargobull.com |

| Silke Hesener: | +49 2558 81-1501 I silke.hesener@cargobull.com |

Download

-

Image: Economic efficiency and safety with the right tyre pressure

-

Press Release: Economic efficiency and safety with the right tyre pressure